IWC introduces Undine® to the USA market

IWC International specializes in product and process hygiene of poultry production lines with 25 years of experience under very strict EU regulations. Our Undine Technology ensures effective cleaning, water conservation, and compliance with the zero-tolerance legislation. Trusted by leading OEMs Marel and Meyn in their latest US poultry production lines.

The general awareness for food safety is shifting and leading up to a more demanding level of hygiene and will eventually result in additional regulations. Following the trend in Europa, customers in North America asked us for the stand alone applications to solve (localized) hygiene problems in their poultry production lines and improve production in general.

We invite you to contact us to get acquainted, we’d like to discuss your specific situation and needs. For your convenience, a Microsoft Teams meeting can be scheduled via this link.

Best regards,

Ton Winters and Twan Koenen

IWC International Inc.

701 Brickell Ave – suite 1550

Miami, Florida, 33131

Innovative Water Concepts International

Our mission is to make cleaning easier and more sustainable all over the world. We succeed in our mission by achieving better cleaning results with less water and less energy. Our ambition is to set a new standard in hygiene with the Undine® cleaning technology.

Innovative Water Concepts International was founded in 2004 by Ton Winters. With his ground breaking invention of the Undine® cleaning technique, he quickly became known as an expert in the field of cleaning in the food industry.

Today we are active in countries all over the world. From our production center and head office in the Netherlands, we ensure that this international network is optimally geared to the needs of our customers. Our local experts know the market and culture so we are always close by.

It al started in the last century with a farmer that wanted to rinse his crop after harvesting. He was caught by surprise when Local authorities suddenly limited the overal usage of water without any warning in advance. He had to come up with a solution to clean his crop while reducing the water usage to stay within the new limits of water consumption.

Meet the inventor

Genius products invented by accident. Everyone uses them once in a while. Think about the microwave, penicillin and champagne. But the Undine® can also be included in this illustrious list. The Undine® has already saved millions of cubic metres of water. But how did it all start?

The local municipality did not want to grant Ton Winters an environmental permit anymore. His farm used too much water. When an air compressor broke down and started spraying a mixture of water and air, Ton came up with an ingenious idea. Could he rinse his leeks with less water? It turned out to be a hit, and Undine® was born.

Get acquainted with the Dutch leek farmer that became a prize winning and world wide entrepreneur in this video:

Facts instead of promises

- Water savings up to 70%, depending on application, but on average 50%

- Energy savings where hot water usage is reduced

- Saving on cleaning chemicals in conveyor belt or crate washers

- Automation and shorter cleaning time saves labor and water costs because cleaning is easier and takes less time

- Savings on maintenance because Undine nozzles are largely self cleaning

- Low installation costs because of the clever design

- Less rejections of the product because of better cleaning results

- Significant and measurable reduced bacteria loads

We focus on specific situations and have a broad view on the whole process.

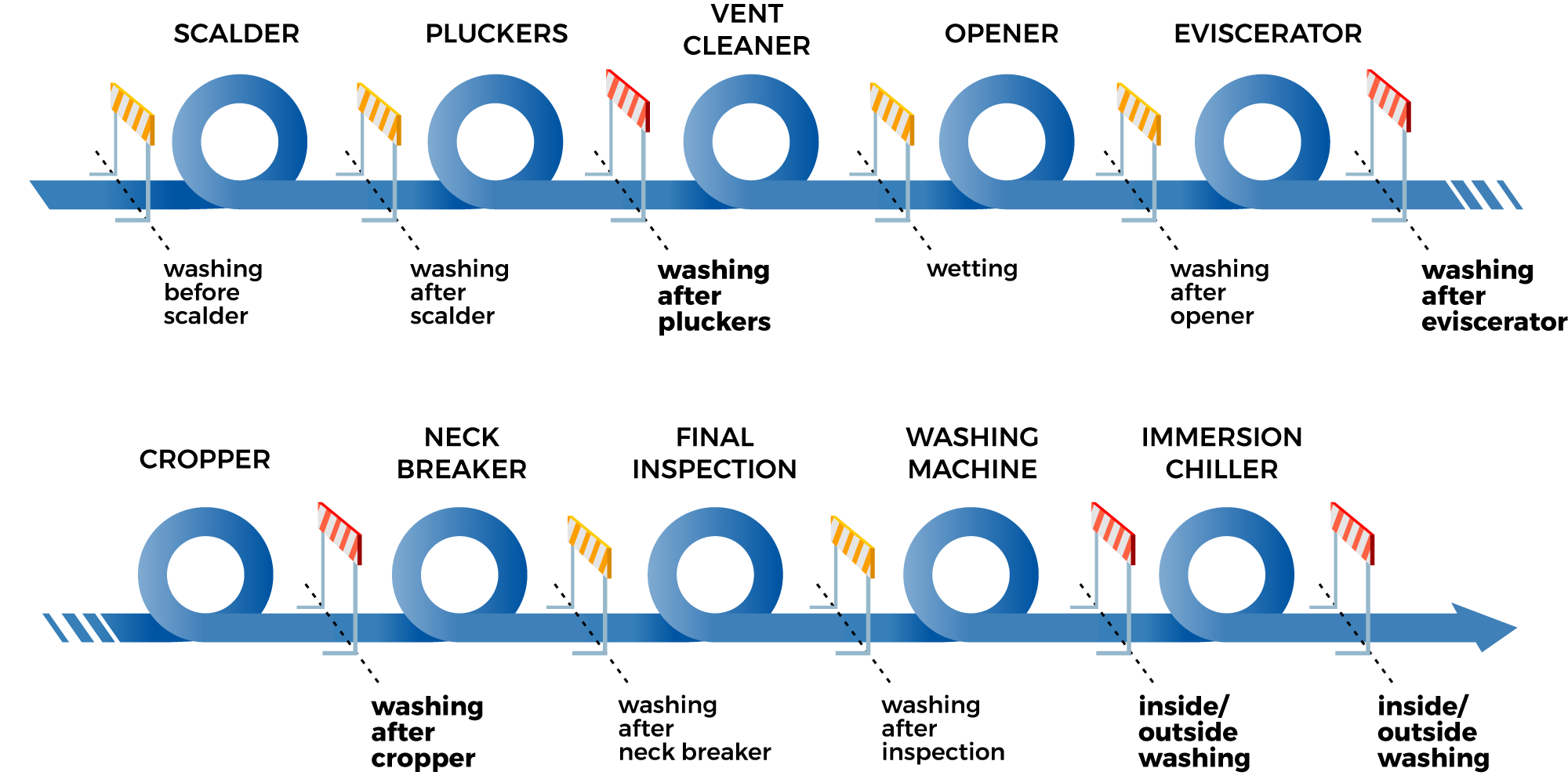

A stand alone part does not make a integrated and holistic hurdle hygiene concept. Following the recent developments in USA on Salmonella and increased number of air chill tunnels, we are now introducing the Undine Hurdle to hurdle concept for the US Poultry market.

The meaning of the word “hurdle” is to create a barrier against something. In this case, it refers to a barrier against contaminations and bacteria to continue to the next process step. The hurdle concept has existed for some time but has been greatly improved by us.

Our Undine® technology significantly enhances the cleaning power of just water. Undine® takes the hurdle concept to a higher level. In some cases, it is even possible to remove specific bacteria such as salmonella and enterobacteria below detectable levels.

Water savings allow for the installation of additional washers, creating extra hurdles while keeping water consumption within acceptable limits. In fact, even with additional washers, Undine® manages to save water. Undine® enables a significant improvement in the overall hygiene level of a poultry processing company. Existing hurdles are made more effective, and thanks to the substantial water savings, additional hurdles that were previously unfeasible can be implemented.

Read more about it in this article.

Our inline Solutions

Although Undine is around for 25 year, the technology is still state of the art and we keep on developing new applications. For the time being we concentrate our efforts in the US at the poultry production industry.

For each step in the production process, we have a cleaning solution that incorporates the benefits of the Undine Technology. Furthermore we have applications for shackle and product carrier cleaning. For conveyer belt and crate or module cleaning.

Apart from cleaning, Undine can optimize the production process itself. For example by decreasing dehydration losses and facilitating defeathering.

Check this page to see our applications in typical situations.

UNDINE® – How does it work?

The Undine Technology is, in essence, simple, as any good technology should be. A simple technique has a simple design, which helps for easy installation and low maintenance.

The science behind our technology is not complicated but counter intuitive. We will compare cleaning with pressurized water (580 psi/40 bar) only and cleaning with Undine. Undine operates with a combination of 145 psi/10 bar of water pressure and 58 psi/8 bar of compressed air.

So, how is it possible that a substantial drop in pressure, in this example, a drop from 580 psi/40 bar to 203 psi/10 bar water pressure, results in better cleaning results while using less water? Intuitively, more pressure means more force, and more force equals less chance for any kind of pollution to stay on the surface of the object that needs to be cleaned.

Yet, this is not the case. Our secret is to break up the water flow into micro droplets and accelerate them at much higher speeds. Our high-speed micro droplets exert more force on the pollution than the jet with only water can.

We have conducted many studies to explain the physics of this and also why Undine penetrates a surface deeper than the waterjet without damaging the surface itself. This is an important factor when cleaning poultry.

+31 (0) 527 745 932

+31 (0) 527 745 932 info@iwc-international.com

info@iwc-international.com