Higher production without exceeding water quota

| Guy Ackermans |

One of our Canadian clients wanted to increase the production, which involved ramping up their production speed. This would, in turn, increase the factory’s water consumption and wastewater output. However, the local government refused to expand the existing permits for these areas, putting the management’s plans in jeopardy.

While analyzing the process to determine where water could be saved, it appeared that the hygiene was not optimal. The chickens were not getting cleaned properly. Although the inside/outside washer used approximately 15 m³ (4,000 gallons) per hour, only 33% of the chickens being visually clean. This equated to 3 liters (0.79 gallons) per chicken in the OEM internal/external washer.

Subsequently, a test was conducted to determine the water volume required to achieve 99% visually clean chickens. It was found that 99% cleanliness was achieved at a water consumption of about 25 m³ (6,600 gallons) per hour, or 5 liters (1.32 gallons) per chicken. However, such an increase in water usage was not permitted and thus was not a viable solution. Canada, like the European Union, has a zero-tolerance policy regarding contamination. Chickens must be 100% visually clean to pass inspection, both inside and out.

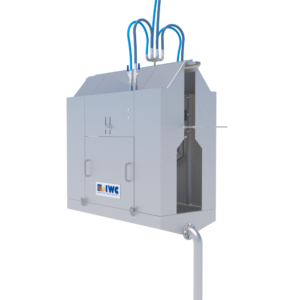

Replacing the OEM washer for an Undine® I/O washer

We decommissioned the existing inside/outside washer and installed an Undine® unit. The high-speed microdroplets of the Undine® system ensured that 99.8% of the chickens were clean, with a water usage of only 6.3 m³ (1,660 gallons) per hour, equating to 1.25 liters (0.33 gallons) per chicken. The Undine® technology thus provides superior cleaning results with significantly lower water consumption.

The results

- The reduced water usage also means less wastewater production. Additionally, there is substantial energy savings as the energy saved on water pump capacity is only 20% offset by the required compressed air.

- The client was also pleased that the Undine® internal/external washer works contactless. This minimizes the risk of cross-contamination and reduces maintenance costs by thousands of dollars annually.

- The biggest advantage for our client was that with a few additional Undine® adjustments in the factory, we were able to create enough capacity to expand production within the water and wastewater quotas set by the local government.

+31 (0) 527 745 932

+31 (0) 527 745 932 info@iwc-international.com

info@iwc-international.com