Longer shelf life, no chemicals, less water usage

| Guy Ackermans |

A customer of ours in Australia experienced an issue in 2021 with maintaining the robustness of the product shelf life. The factory operates multiple production lines, each with a production speed of 13,000 chickens per hour. These lines were equipped with cleaning nozzles for washing the product, where additives were added to the water. The purpose of these additives was to disinfect the carcasses to achieve an acceptable shelf life. However, the application of these chemicals did not yield the desired effect. The shelf life was disappointing, and consumers complained about it.

Our dealer heard about the issues and suggested an Undine® solution. Since no alternative solutions were offered by the OEMs, the customer was interested in IWC-International’s approach with Undine®. Being the first on the continent, the customer requested a test. We set up the test as follows:

Comparison test

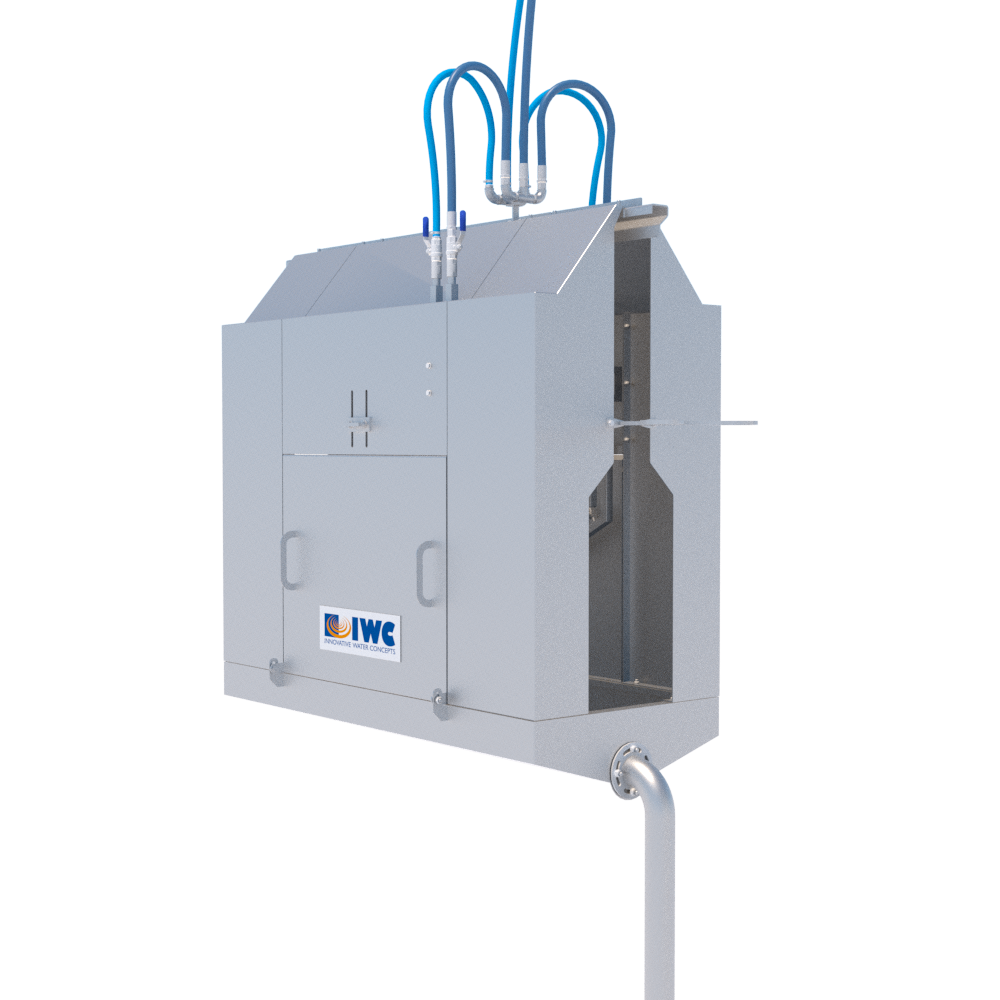

One of the lines used only clean drinking water without any additives. This line was equipped with two Undine® washers to replace the existing washers. The first unit was an Undine® external washer placed immediately behind the plucker. This location was deliberately chosen because there is a short period of about 20 seconds after the plucker during which the follicles and pores remain open. During this time, Undine®’s high-speed microdroplets can remove contaminants, including those embedded by the plucking fingers in the follicles. These contaminants often contain pathogens that negatively affect shelf life. Once the follicles close after about 20 seconds, any remaining contamination (including pathogens) is no longer accessible. This means that adding chemicals becomes ineffective as they can no longer reach the pathogens in the now-closed follicles. Therefore, increasing the concentration or amount of chemicals does not make a difference.

The second unit was an Undine® internal/external washer at the end of the evisceration department to remove all remaining contaminants from both the inside and outside of the carcass. These contaminants include feces, digestive tract contents, and organ parts. This resulted in a clean carcass that meets the Australian veterinary inspection standards.

Laboratory proof

The customer then conducted laboratory measurements, comparing the slaughter line equipped with Undine® to the other slaughter lines within the group. The manufacturer’s aim was to determine the microbial count on both lines through these lab tests. The customer hoped that the production line using chemicals and the one using only Undine® with drinking water would achieve similar microbial counts. After months of testing, it was found that the Undine® line consistently had a significantly lower microbial count than the “chemical line” under comparable conditions.

Conclusion

The most important outcome for the customer was achieving the shelf life goal. Additionally, they realized a 50% reduction in water usage in the evisceration department and savings in wastewater management and energy consumption. These laboratory results led to the modification of all other production lines to Undine® washers starting in 2022.

Currently, we are in the process of providing the company with Undine® shackle cleaners, as there is always room for improvement in cleaning processes. The primary focus for the shackle cleaners is to achieve excellent cleaning results. Clean shackles and a clean production chain are the goals. The additional benefits of saving water, time, and labor are secondary but contribute to an extremely short payback period (approximately three months).

+31 (0) 527 745 932

+31 (0) 527 745 932 info@iwc-international.com

info@iwc-international.com