Performance issues of Final Inspection Machine solved with Undine®

| 17 May, 2024 | Guy Ackermans |

A client of ours in Poland had increased their line speed from 9,500 to 13.000 birds per hour. Due to this capacity expansion, a major issue arose. The chickens were no longer clean, and the veterinarian disapproved. The existing Final Inspection Machine could barely handle the old line speed of 9,500 (bph). With the higher line speed, organ parts were left behind in the carcass, leading the veterinarian to reject the chickens, resulting in fines.

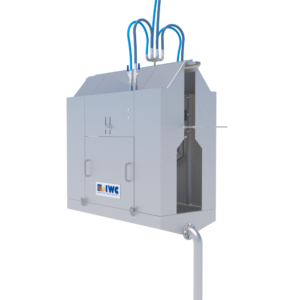

A Final Inspection Machine has nothing to do with a final check, although the name may suggest so. In fact, the machine is a vacuum cleaner for leftover organ parts and any loose skin and flesh inside the carcass. The client then attempted to order an additional Final Inspection Machine with required high capacity from the OEM. However, they faced an extremely long lead time from the OEM while the veterinarian required immediate action. We were able to provide a short-term solution by delivering an Undine® inside/outside washer that could accommodate the increased line speed while using 50% less water. The Undine® inside/outside washer was able to remove all organ parts, satisfying the veterinarian.

Lower costs and better hygiene

The acquisition cost of the Undine® inside/outside washer was less than 20% of their OEM’s Final Inspection Machine. Additional benefits of the Undine® washer includes contactless cleaning, eliminating the risk of cross-contamination, and significantly lower maintenance costs compared to the FIM. The reduced number of rejections and fines by the veterinarian resulted in a payback period of less than 12 months.

We are currently in discussions with the client regarding the complete Undine® hurdle concept to address their other issue of significant variation in the size and weight of chickens. Additionally, we will significantly reduce the water usage of the entire factory.

+31 (0) 527 745 932

+31 (0) 527 745 932 info@iwc-international.com

info@iwc-international.com