An Undine® I/O washer has a payback time of several months

This is all you need when overhauling our I/O-washer

With a spanner and a handfull of gaskets you’ll do the job. Parts and labor per unit: max € 250.

It’s the right moment to replace your rotating I/O washer, when…

… a major overhaul is impending;

… you want a significant reduction of maintenance costs;

… you want to cut at least 50% of your water usage;

… you want to save on the high daily costs of sanitation.

Purchase an I/O washer from IWC-International and almost instantaneously earn it back.

The rotating I/O washer within the evisceration department of a poultry processing facility is a costly piece of equipment that demands significant maintenance. Moreover, it consumes 8,500 liters of water… per hour. We are more than happy to calculate your savings and the cost of

ownership for your specific situation.

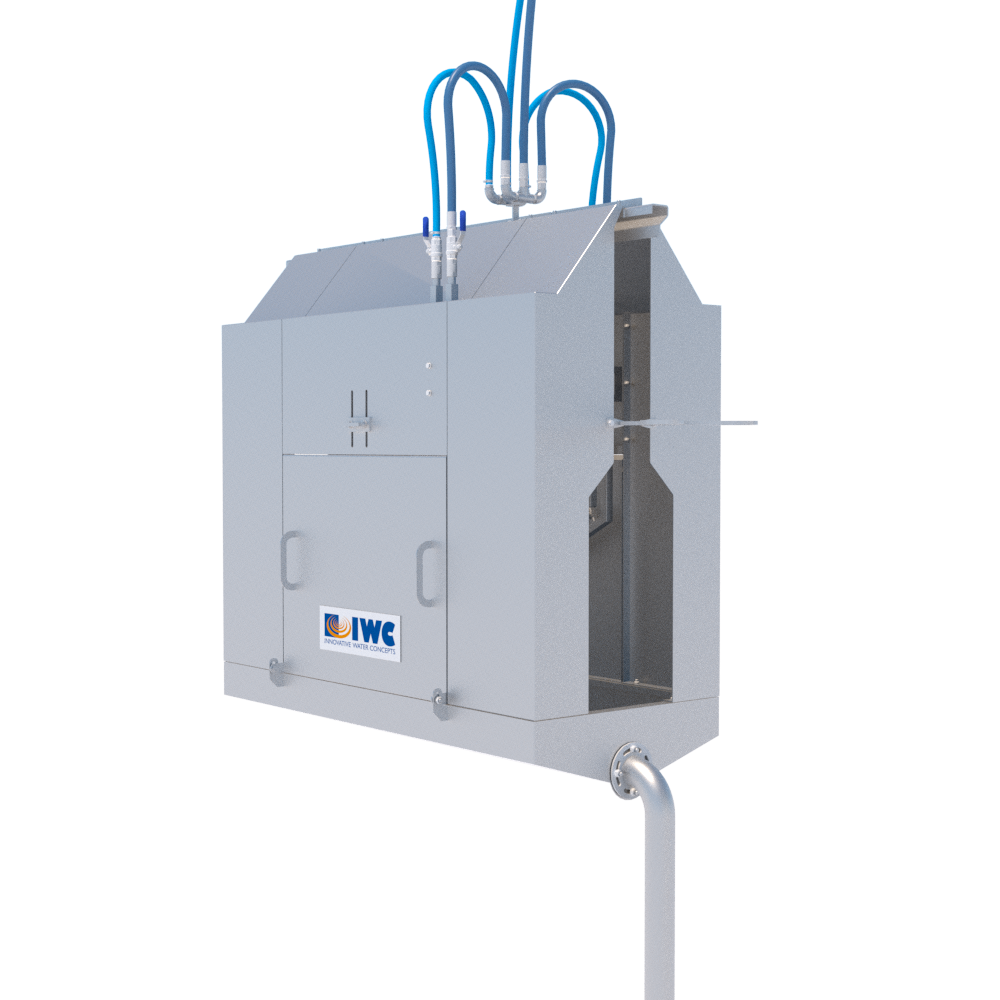

Our inline I/O washer is a sustainable alternative

Equipped with Undine® microdroplets (air/water mixture) technology, the system operates contactless. Minimal maintenance is required due to the absence of moving parts. The lifespan of our I/O washer is at least 15 years. Furthermore, our technology stands out for delivering superior cleaning results compared to the rotating I/O washers offered by major OEM’s.

+31 (0) 527 745 932

+31 (0) 527 745 932 info@iwc-international.com

info@iwc-international.com