Undine technology makes IWC inside-outside washer unique

| 15 December, 2020 | Twan Koenen |

Product hygiene and food safety are top priorities for poultry processors. With the flexible and modular hurdle-to-hurdle cleaning system and the application of the unique Undine technology, IWC-International provides an important contribution to optimum product hygiene during the entire processing procedure. In this article we will elaborate on the technique behind the contactless cleaning inside and outside with the Undine mix.

Always the right impact

At its core, our Undine technology is a combination of pressurized air and water. This mix is created in the mixing chamber and directed via nozzles to the surface/product to be cleaned. These mixing chambers together form a manifold. Several manifolds are brought together in a cabin. Such a cabin is filling the role of a hurdle, as intended in the hurdle-to-hurdle concept. So multiple cabins together complete the hurdle-to-hurdle concept. The droplets created by this technology are about as small as bacteria and feel like stinging needles because many of them touch a surface in succession. This ensures very intense cleaning, even in small cavities and hard-to-reach places, with very low water consumption due to the small droplet size. Due to the sophisticated Undine technology with its small droplet sizes at high speeds, there is no risk of damaging delicate products such as meat or soft fruit. Something that is the case when using ‘normal’ high-pressure cleaning due to the larger drops.

Each step has its own function

The Undine mix is therefore used in every step (hurdle) of the cleaning process in poultry processing. This can start before the scalding process, immediately after the pickers and after the eviscerator, cropper, and inside-outside washer. Basically, the technique used and the mixture of compressed air and water are identical. For each hurdle, the cabin is optimized for that application. For instance, by different positioning and composition of the number of Undine mixing chambers. After all, every external and internal part of the product must be cleaned intensively. And that without the mixing chambers coming into contact with the product. This could lead to cross-contamination with bacteria and dirt. In addition, the working pressure can be adjusted depending on the hurdle. In this way, cleaning results and water consumption can be adjusted without causing damage, even when cleaning the most delicate and small product parts.

Swirl and atomisation

Besides the fact that the Undine mix is very powerful on a micro level, this technology makes it possible to create a vortex inside the product from the outside, which is used optimally for the internal cleaning of products in particular. The vortex is created above the product and directed into the chest cavity. In combination with the fine atomization and high speeds, this is extremely effective for the full non-contact cleaning of the inside of the product.

The technical essence of Undine

In several articles, including this one, we have discussed the practical applications and advantages of our Undine technology. Below, we summarize the essence of Undine for you, supported by images and videos.

Characteristics of cleaning in general:

- Cleaning with water is based on the principle of mechanical force and the energy that you give to the water to remove dirt.

- The mechanical energy that the water exerts on the dirt/soiled surface is a result of the mass (drop size) and speed of this drop.

- The velocity (and droplet size) is determined by the combination of water pressure and nozzle opening. in the nozzle the pressure is converted into speed (kinetic energy).

Characteristics of conventional cleaning technology (only water under pressure):

- Conventional high-pressure cleaners using water have larger droplets with relatively lower velocity compared to Undine. The energy is also determined by the speed and mass of the water.

- In order to get smaller droplets with higher speed, conventional high-pressure cleaning with water requires much higher pressures in combination with much smaller nozzle openings. And it takes more energy to create these higher pressures.

Characteristics of the Undine® cleaning technique:

- Undine® uses compressed air with water under predetermined line pressure (pressurised water) in the mixing chambers. Depending on the application, we work with pressures of between 5 and 25 bar in the food industry. Pressures up to 100 bar are technically possible with Undine.

- With Undine, the water droplets in the mixing chamber are shaped for their intended purpose by means of compressed air. The speed of the water drops is much higher than with conventional high-pressure cleaners. Thanks to this technology, the speed of the droplets is up to 5 times higher than with conventional high-pressure cleaners.

- Thanks to the Undine technology, we can create very small drops at much lower water pressures and by adding 6-8 bar compressed air, in combination with large nozzle openings. Blockages caused by lime or other fine particles in the water, for example, no longer occur.

- Undine is very energy efficient: the energy (air & water pressure) is very efficiently converted into cleaning energy. Undine works with lower water pressures and gives a higher energy to the water droplets. The energy required for cleaning is further reduced by the much lower water consumption.

- With Undine, we give the water a much higher energy and we create extremely smaller droplets. This combination ensures a much more effective cleaning, even in very difficult to reach places where bacteria like to settle. Undine is therefore extremely effective in removing micro-contaminants, such as bacteria.

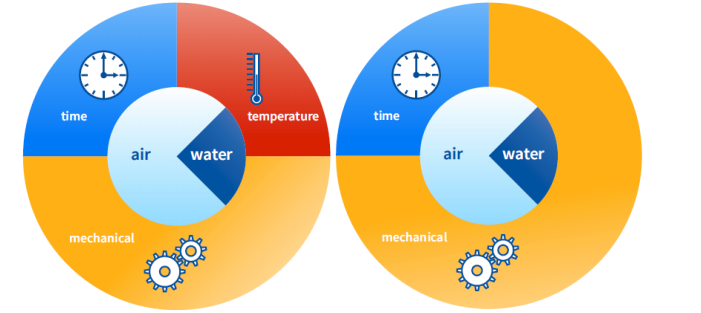

- With the Undine mix of compressed air and small water droplets, it is possible to have two streams come together that boost each other. In Undine cleaning, we allow the compressed air-water to mix and join them from two sides above the product to be cleaned. For example, with Undine it is possible to have 2 streams from e.g., the back and breast side coming together, creating a turbulent vortex which can clean the inside of products such as the breast cavity very effectively without any contact.

- With Undine, there is no contact between the equipment and the product during the entire cleaning process. Therefore, there is no risk of cross contamination by contaminated machine parts.

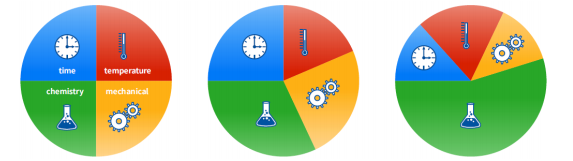

Media Water & Air and Mechanical, Time and

Temperature cleaning aspects

Figure 3: Sinner circle with cold water and air only.

Also choose for cleaning with our Undine technology

IWC-International has the modular hurdle-to-hurdle cleaning technique based on the unique Undine technology also available for you. Would you like to know more about this or are you interested in a suitable offer? Then get in touch with us!

+31 (0) 527 745 932

+31 (0) 527 745 932 info@iwc-international.com

info@iwc-international.com