Proper moistening with Undine offers many advantages

| 15 December, 2020 | Twan Koenen |

During the food production process, products are regularly moistened. This may be to cool down the product or to prevent or strongly reduce the dehydration of the product. In the processing of poultry and red meat, IWC’s unique Undine technology is used, among other things, for more effective moistening of the sensitive product. In this article we zoom in on the moistening of the product with Undine, why this is done and what advantages Undine offers.

Moistening is cost-saving and increases turnover

The primary purpose of wetting is to achieve the right product temperature (core temperature) more quickly and to prevent or minimise the dehydration of products. Humidification reduces dehydration losses to a minimum and this has an enormous financial impact, especially when processing in high capacity slaughterhouses. It is for this reason that many processors use humidification by means of spray cabins in their air chill tunnels. Due to the used spray patterns that are not always perfect, there are still some losses despite the humidification, which at high capacities can easily add up to a yearly loss of revenue of half a million euros or even more.

Tangible financial benefits

Without Undine, we see dehydration losses of 1.5 to 3%. This means that per kilogram of product, only 970 grams remain for sale. You can calculate for yourself what this means for your company in terms of annual turnover. Thanks to the sophisticated Undine technology, we can reduce these drying losses even further in existing tunnels with product humidification, at the same time as reducing the water consumption. In practice, results of 0.2% to 0.5% less dehydration loss have already been achieved by using Undine. At the same time, water consumption for humidification in the cooling tunnel has been reduced by 50% to 70%. At higher capacities, this represents a financial benefit of a additional 200,000 to 500,000 euros.

Regulated and effective water mist

Proper humidification of sensitive products, such as poultry and red meat, is a very delicate process. It is all about covering the entire product surface with an evenly distributed fine water mist. Too much water or big droplet size runs off the product unused and too little water leaves uncovered areas that can still dry out. The Undine technology ensures during this step in the entire process that not too much water is applied and that the fine water particles as a kind of mist – comparable to dew – do their work extremely effectively. The Undine mix of water and compressed air actually breaks down the water into a huge number of small water droplets.

Product cooling and dehydration prevention

Because each water droplet is so small, it immediately takes on the temperature of the surface to which it is applied. This droplet is then replaced by the next droplet and so on. The mist in the Undinemix that is applied for this purpose ensures a sophisticated and optimal humidification of the total product surface. This cools the product and protects it from dehydration by the cold, dry air that must first break through this layer of water before it can extract moisture from the product. To achieve the optimum effect, the application of the water film is repeated at intervals and applied again before this layer has evaporated.

During the food production process, products are regularly moistened. This may be to cool down the product or to prevent or strongly reduce the drying of the product. In the processing of poultry and red meat, IWC’s unique Undine technology is used, among other things, for more effective moistening of the sensitive product. In this article we zoom in on the moistening of the product with Undine, why this is done and what advantages Undine offers.

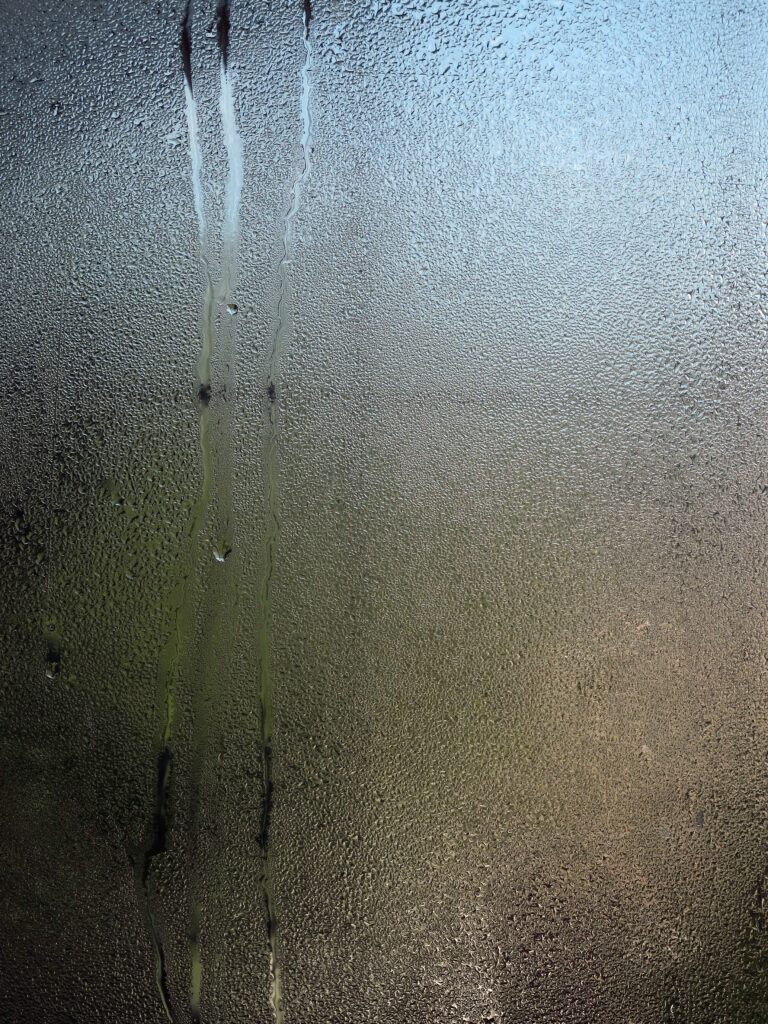

Example of large and small drops that are too far apart and thus do not cover the entire surface Example of drops sliding down causing lines Example of how the whole surface is just fogged up

The disadvantages of conventional wetting

Three disadvantages can be distinguished:

- Too low water pressure: In slaughterhouses where the cleaning and humidifying of poultry and red meat is done in a conventional way, the water pressure is often too low. This results in a coarse atomisation with water droplets that are too large. Moistening with large droplets causes them to roll downwards due to their weight. Furthermore, the total product surface will not be optimally wetted and uncovered areas will remain between the drops.

- Clogging of nozzles with small openings: with conventional cleaning and humidifying, the atomisation is determined by the combination of water pressure and the nozzles used. In order to achieve the desired effect, a very small orifice is chosen, which in turn encourages the clogging of this type of nozzle by lime and dirt. This jeopardises the humidification process.

- Additional maintenance: The use of small nozzles – which can quickly become blocked – must be compensated for by installing special filters in the piping system. This, in turn, requires additional and recurring maintenance of the filters and nozzles. During this whole process, unnecessary amounts of water are wasted.

With Undine, these problems belong to the past.

Undine mist, how it works!

The secret behind the very fine and highly effective mist lies in the way the mix of compressed air and water is produced in the Undine mixing chamber. The very fine atomisation and vortexing of the water-air mixture makes it possible to work with low water pressure and relatively large nozzle passages, while still using less water. With Undine, this whole process of intensively and effectively cleaning and optimally humidifying poultry and red meat takes much less energy. It is often possible to work with the standard water pressures. The very fine Undine mist also works much more efficiently. Undine creates a win-win situation for your company in all respects.

This is why you should choose Undine

As you can see, there are plenty of reasons to switch to cleaning and humidifying poultry and red meat with Undine. The most important advantages are summarised below.

- By atomising small, light drops of water mixed with compressed air, you get a very effective cleaning and humidification of your products and you use (waste) much less water.

- The fine Undine mist/spray finds its way much better into hard-to-reach places in and on your product and spreads itself evenly over the entire product surface.

- The super light mist forms a thin water film that stays on the surface with a very good, complete coverage.

- Cleaning and wetting with Undine requires much less maintenance than conventional high-pressure systems due to the low water pressures and large nozzle passages.

Would you like to know more about the application of Undine in your company? Please contact us for expert and honest advice or a suitable offer. IWC is at your service!

+31 (0) 527 745 932

+31 (0) 527 745 932 info@iwc-international.com

info@iwc-international.com