Improving hygiene in poultry processing by taking the hurdle concept to the next level

| 4 September, 2020 | Twan Koenen |

The so-called hurdle concept has been around in poultry processing for many years now. Scientists have done lots of research on the hurdle concept and the poultry industry has implemented many of their findings in their processes, in order to improve hygiene. In fact, most process implementations in the industry can be understood in the context of the hurdle approach.

However, many poultry processing plants are struggling with water consumption and water pressure, which leads to a less hygienic process and end-product. Our Undine® technology takes the hurdle approach to the next level. Undine® makes it possible to significantly improve the overall hygiene level of a poultry processing plant. Existing hurdles cannot only be made more effective, additional hurdles that were not feasible before can be created, thanks to the huge water savings that the use of Undine® brings.

The hurdle concept: creating hurdles improves hygiene

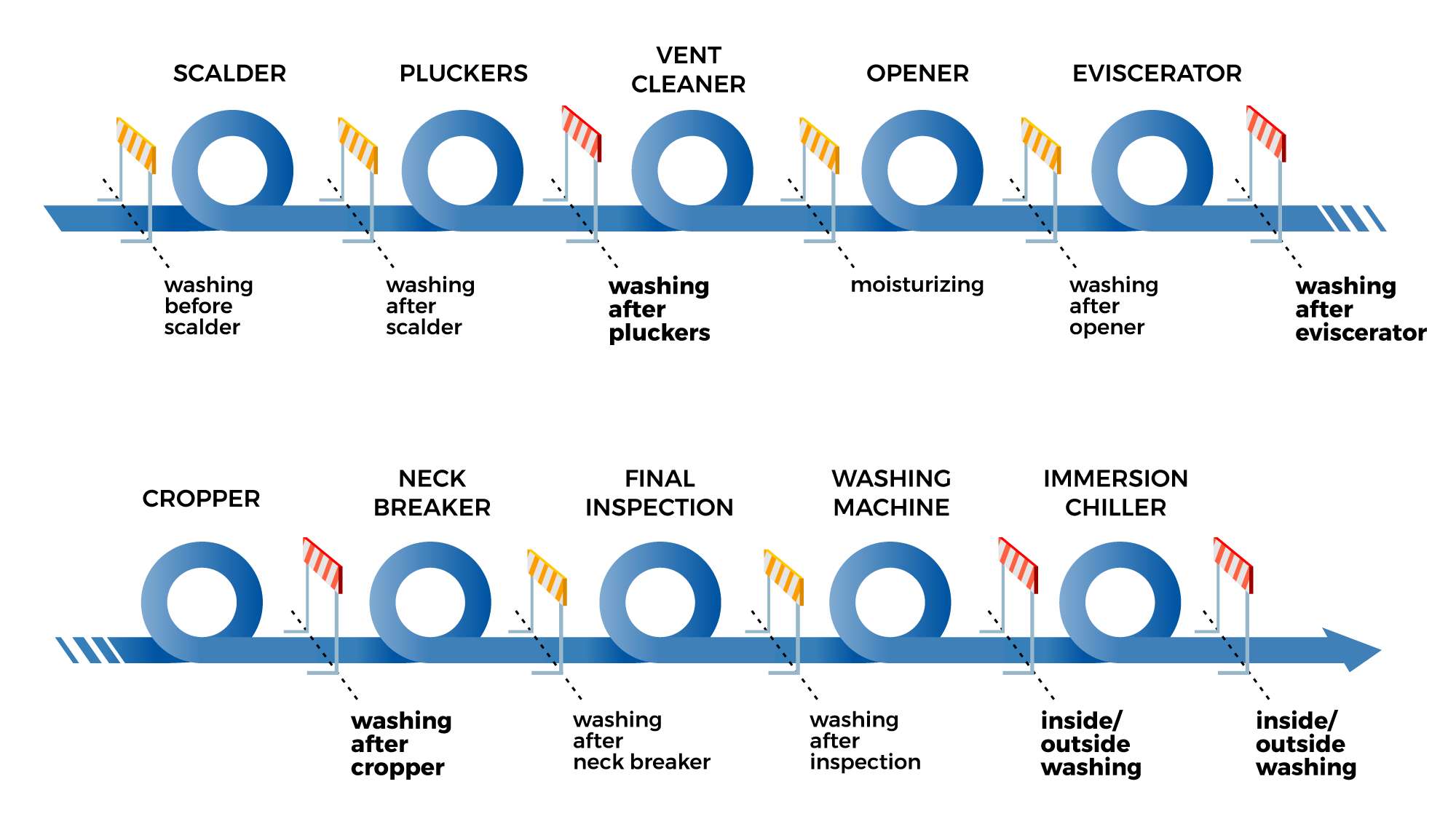

The main principle of the hurdle concept is to prevent dirt and bacteria from passing on to the next processing step. For example, loose feathers, attached to skin or shackles, must be kept from entering the evisceration process. In almost all cases, a hurdle consists of a washing step: a nozzle on the machine or cabinet dedicated to this function. The better dirt and bacteria are removed, the less likely bacteria are passed on further into the process and eventually end up in or on the end products

The hurdle concept separates processing steps based on hygiene

The hurdle concept means processing steps are separated based on hygiene. When products are rehung into another line with a higher hygiene status, they have to be as clean as possible. Therefore, processing plants are separated into different hygiene zones, such as the slaughter- and evisceration department.Moreover, machine manufacturers have made provisions (hurdles) to ensure hygiene within each line.

Most processing plants are struggling with water pressure and consumption

The results of all provisions and cleaning steps depend strongly on the water pressure. Some plant managers struggle to achieve the correct water pressure, because the water supply is insufficient. Others have to limit water pressure in order to stay within limits of water usage. Both cases result in a less hygienic process and end product, because usually, there is a trade-off between hygiene and water consumption. While a processor might still meet the legal requirements, it is often not enough to meet the industry’s quality standards. These are often stricter, in order to create added value. Undine® solves this dilemma by simultaneously reducing water consumption and improving hygiene.

Take the hurdle approach to the next level with our Undine® technology

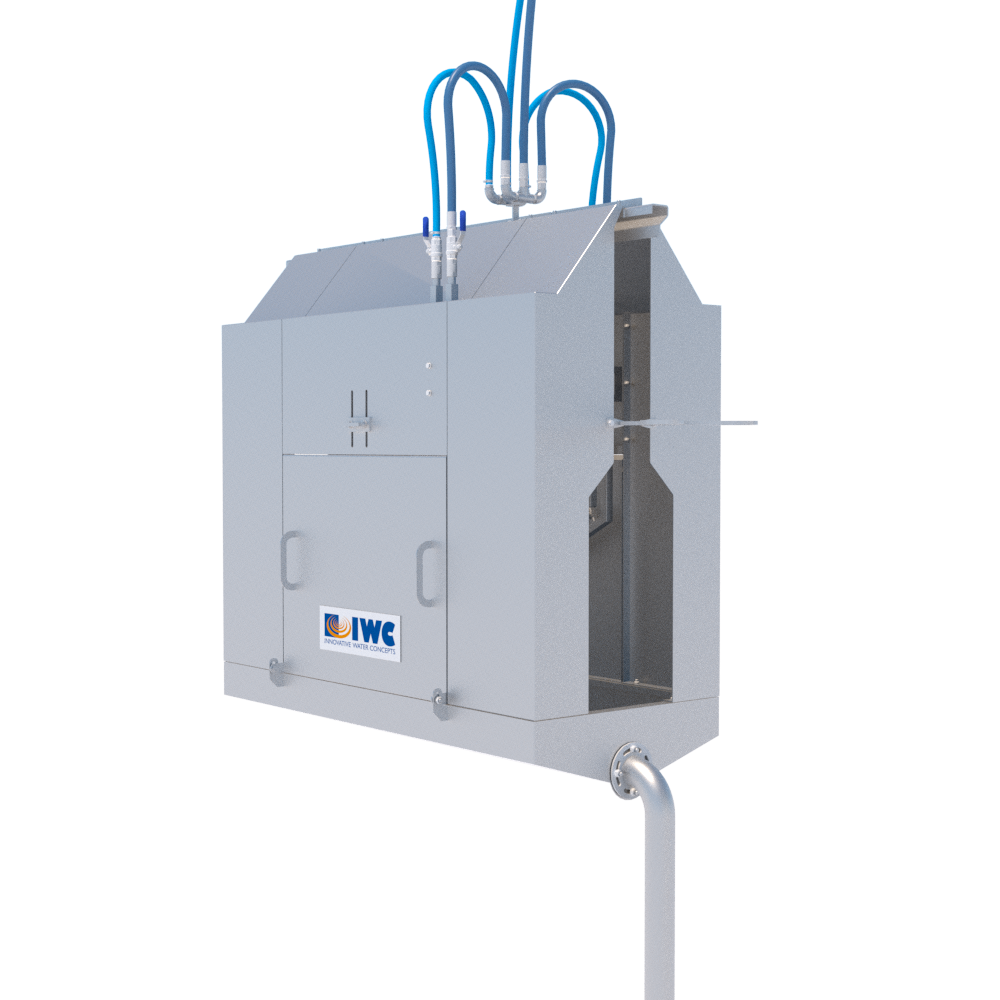

Our Undine® technology boosts the cleaning effect of water enormously. Water and air are mixed under pressure in Undines® mixing chambers. It results in effective cleaning, better hygiene and extremely low water usage. This takes the hurdle approach to the next level. In some cases, removing specific bacteria such as salmonella and enterobacteria even becomes possible.

Undine® makes it possible to create additional hurdles

Saving water makes it possible to install extra washers, thus create extra hurdles, while staying within accepted limits of water usage. In fact, even with the extra washers installed, Undine® still manages to save water.

The benefits of a washer after the cropper

It’s highly uncommon for poultry processing plants to have washers installed behind the cropper. Nevertheless, we usually install an extra washer behind the cropper. This has a huge effect on removing salmonella bacteria from poultry. Obviously, this results in cleaner birds, less rejections and better hygiene.

Our cleaning solutions for poultry processing plants

Undine® makes it possible to significantly improve the overall hygiene level of a poultry processing plant. Existing hurdles are made more effective, and additional hurdles that were not feasible before, can be created thanks to the huge water savings.

Our solutions for creating hurdles in poultry processing:

- Before scalding (new)

- On pluckers (improved)

- After plucking (improved)

- Venter (new)

- Opener (new)

- Eviscerator (improved)

- Cropper (new)

- Neck breaker (new)

- Final inspection machine (new/improved)

- I/O washer (improved)

An overview of the process from entry to departure can be found here.

We know which solutions are right for you

Would you also like to improve hygiene and save on water, energy and personnel costs? Please feel free to contact our experts. They are happy to provide personal advice. Which solutions suit you best, depends on your specific plant configuration and products.

+31 (0) 527 745 932

+31 (0) 527 745 932 info@iwc-international.com

info@iwc-international.com